TRAPIS Roadshow

Come and join the TRAPIS Roadshow Tour and discover how Mimaki is transforming textile printing.

Local sessions are now available in all regions. Join us and be part of the experience with Mimaki!

EXPLORE OUR NEW TRAPIS TECHNOLOGY – HANDS ON!

Discover the future of textile printing at Mimaki’s TRAPIS Roadshow Tour! At our interactive open houses and workshops, you will get hands-on access to our new, easy-to-use Transfer Pigment System (TRAPIS).

Learn how TRAPIS simplifies textile printing on a variety of fabrics, including natural fibres like silk and cotton, and experience this eco-friendly solution for yourself.

WHY TRAPIS?

Versatility: Print on any fabric – cotton, silk, polyester, nylon and more – for ultimate flexibility from interior fabrics to apparel. TRAPIS allows you to print only what you need, minimising waste and reducing costs – ideal for small business.

Simplicity: All you need is a Mimaki printer and high-pressure calender. No pre-treatment, no post-processing and minimal maintenance. Plus, no specialised knowledge required – anyone can operate it!

Sustainability: TRAPIS offers a waterless, eco-friendly printing solution, reducing water use by up to 90% and cutting carbon emissions by up to 92%.

EVENTS SCHEDULE: REGISTER NOW!

View our current event schedule here and register directly to your preferred TRAPIS Roadshow event. Simply click on the event link of your choice below and submit the attached form. Your registration will be forwarded to your local dealer who will confirm your registration. This schedule will be updated regularly, so stay tuned for more events to follow!

Register now for:

United Kingdom: TRAPIS Roadshow – UK at Hybrid Services, Crewe on 29/01/2025 - 30/01/2025 More info

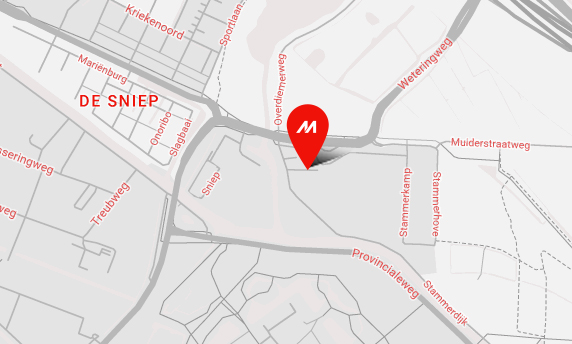

Netherlands: TRAPIS Roadshow – Nordics at Mimaki Europe B.V, Diemen on 20/02/2025 - 21/02/2025 More info

Hungary: TRAPIS Roadshow – Hungary at Sericol Hungary Kft, Budapest on 26/02/2025 - 27/02/2025 More info

France: TRAPIS Roadshow – France at Mimaki Europe Tremblay en France, Paris on 05/03/2025 More info

Netherlands: TRAPIS Roadshow – EMEA at Mimaki Europe B.V, Diemen on 27/03/2025 - 28/03/2025 More info

TRAPIS. Simple, waterless textile printing technology.

TRAPIS provides a simple two-step process, consisting of a Mimaki TS330 printer in combination with a TP ink set, where the design of choice is printed onto Mimaki Texcol paper, which is then transferred to the fabric via the dedicated heater unit with calender (allowing a pressure of 5-8 bar). Unlike both analogue and digital conventional dye-printing methods, TRAPIS enables printing and commercialisation with virtually no water.