CREATIVITY DEFINES THE USE

Modular high-end flatbed cutting plotter

High-end flatbed cutting plotter for fast, precise cutting and versatility

The table size can be expanded and supported tools, including tangential, reciprocating, V-cut, creasing, milling and eccentric cut, can be added to support business growth.

Unique features

- High-Speed Production

Achieve speeds of 100cm/s with 0.7G acceleration to maximise productivity.Achieve class-leading speeds of 100cm/s with 0.7G acceleration, significantly increasing production efficiency. This high-speed capability reduces turnaround time and increases throughput, effectively tackling demanding tasks such as package cutting and milling designs with precision.

Achieve speeds of 100cm/s with 0.7G acceleration to maximise productivity.Achieve class-leading speeds of 100cm/s with 0.7G acceleration, significantly increasing production efficiency. This high-speed capability reduces turnaround time and increases throughput, effectively tackling demanding tasks such as package cutting and milling designs with precision.

The CFX Series improves project completion rates, increasing profitability and customer satisfaction.

- Multi-Tool Capability

Configure up to four tools simultaneously for efficient productivity and reduced tool changes.The CFX Series features a multi-head that supports up to four tools simultaneously. This reduces manual tool changes, minimises downtime and streamlines production. With tools such as tangential, reciprocating, V-cut, creasing, milling and eccentric cut, it offers flexibility for applications ranging from packaging to signage, improving workflow efficiency and reducing operating costs.

Configure up to four tools simultaneously for efficient productivity and reduced tool changes.The CFX Series features a multi-head that supports up to four tools simultaneously. This reduces manual tool changes, minimises downtime and streamlines production. With tools such as tangential, reciprocating, V-cut, creasing, milling and eccentric cut, it offers flexibility for applications ranging from packaging to signage, improving workflow efficiency and reducing operating costs.

- Expandable Cutting Area

Connectable tables with toggle function expand the work area by up to 5 metres for large projects.The standard CFX-2513 can be easily expanded with one (CFX-2531) or two (CFX-2550) additional tables to a cutting area of up to 5 meters. The toggle function further improves efficiency by dividing the extended table into two areas; one for processing while the other is used to set up the next job.

Connectable tables with toggle function expand the work area by up to 5 metres for large projects.The standard CFX-2513 can be easily expanded with one (CFX-2531) or two (CFX-2550) additional tables to a cutting area of up to 5 meters. The toggle function further improves efficiency by dividing the extended table into two areas; one for processing while the other is used to set up the next job.

This flexibility is ideal for handling oversized materials and adapting to evolving production requirements, ensuring efficient processing of large or complex jobs.

- Advanced Camera Features

The camera unit reads crop marks and the media edge for precise backside cutting and creasing, ensuring high accuracy and clean finishes.Place the board face up so that the camera detects the registration marks and media edge; flip the board over and it is cut from the back, where the high-quality V-cut creates 90° notches for perfect folding.

The camera unit reads crop marks and the media edge for precise backside cutting and creasing, ensuring high accuracy and clean finishes.Place the board face up so that the camera detects the registration marks and media edge; flip the board over and it is cut from the back, where the high-quality V-cut creates 90° notches for perfect folding.

This technology ensures precise alignment and automatic correction of cut paths, reducing errors and waste. It enhances accuracy and improves overall efficiency by automating complex tasks.

Tools for every application to Precision Printing

The CFX Series features a multi-head that supports a variety of cutting, creasing and routing tools, providing flexibility for applications ranging from packaging to signage.

High precision tangential units with a maximum pressure of 30kg can be extended with V-cutting and creasing tools for folding applications.

Reciprocating tools with different amplitudes and strokes allow for applications with stiffer or thicker materials up to 54mm.

A router unit is available for cutting and shaping harder materials such as wood, acrylic and aluminium composite panels.

And for the occasional sticker sheet, the eccentric cutter with drag knife is available.

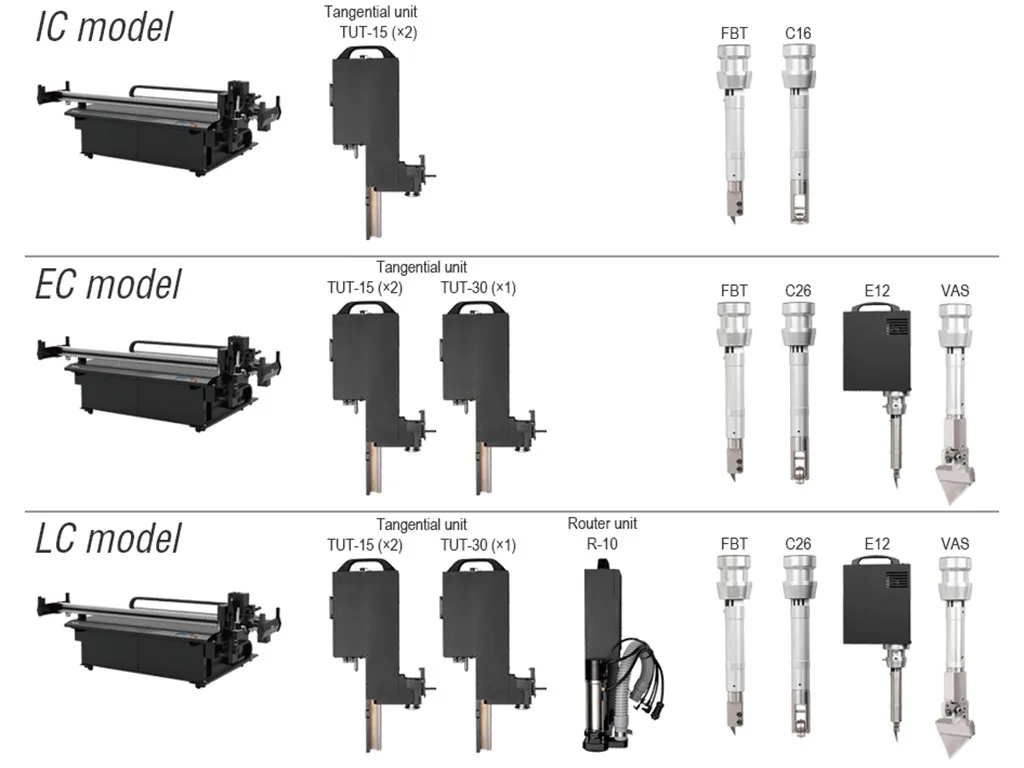

Set models to Precision Printing

Choose from three standard toolkit models to suit your cutting business. Additional tools can be purchased at any time as your business grows and your applications expand.

The IC model is our entry-level model, allowing you to maximise the use of minimal tools to start producing packaging and general sign graphics.

The EC model, with the addition of a reciprocator and V-cut, supports all packaging and fixture/display production by cutting various types of corrugated board.

And the LC model, with the addition of a router (for milling), supports the production of general sign graphics, including cutting acrylic and aluminium composite panels.

The CFX Series is a versatile device…

suitable to produce a wide range of materials and applications.

Sampling, packaging, signage and advertising, POP and POS displays, industrial production, acrylic decorations, flexo plates, cardboard, corrugated and rigid boards, furniture and home decor, aluminum-composite board, packaging foams and industrial rubbers.

SIGNAGE

DISPLAY GRAPHICS

PACKAGING

ALUMINUM-COMPOSITE PANELS

ACRYLIC AND PLASTICS

CARDBOARD AND CORRUGATED BOARDS

The CFX Series cutting plotter features Mimaki Core Technologies that deliver exceptional quality, maximize productivity, and minimize risks that can delay production. See below list of core technologies that are included in the CFX Series.

For superior cutting

- Crop Mark Detection, for a high accurate cut

- Half Cut, to reduce manual labour

- Over Cut, for easy weeding

- Corner Cut, for the perfect contour cut

CFX Series Printer Specifications

| Item | CFX-2513 | CFX-2531 | CFX-2550 |

| Effective cutting range (X x Y) | 1,300×2,540mm | 3,190×2,540mm | 5,080×2,540mm |

| Max. media size to be set (X x Y) | 1,890×2,570mm | 3,780×2,570mm | 5,670×2,570mm |

| Drive system | X/Y-axis: AC servo Z/θ-axis: DC servo | ||

| Max. speed | 1,000mm/s | ||

| Max. acceleration | 0.7G | ||

| Z-axis pressure | 30kg | ||

| Static accuracy*1 | Repetitive accuracy:±0.03mm Distance accuracy:±0.1mm Right angle:±0.5mm/1,000mm Origin reproducibility:±0.15mm | ||

| Max. cutting height | E35: 54mm E60: 54mm V45: 20mm VAS: 20mm FBT: 10mm C16: 54mm C26: 54mm C60: 20mm | ||

| Max. weight of board media | 50kg/㎡ or less | ||

| Command | MGL | ||

| Receive buffer capacity | 22M | ||

| Interface | RS-232C/Ethernet | ||

| Safety standard | VCCI classA; FCC classA; CE marking; CB report (EN62368); UL62368-1 Machinery Directive; RoHS; REACH | ||

| Power supply | 200 V to 240 V single-phase 50/60 Hz 2kW or less | ||

| Power consumption | 3kW or less | ||

| External dimensions [WxDxH] | 4,050×2,150×1,250mm | 4,050×4,050×1,250mm | 4,050×5,950×1,250mm |

| Main unit weight | 380kg | 580kg | 780kg |

| Installation environment | Usable temperature:5℃~35℃, Usable relative humidity: 35~75%Rh, Guaranteed accuracy temperature: 20℃~25℃, Accuracy guaranteed relative humidity: 35~65%Rh, Temperature gradient: ±10℃/h or less | ||

| Software attached | FineCut/Coat 9 | ||

Cutting Design Software

Mimaki provides versatile cutting design software that allows for precise control, simplified design, and efficient cutting.

CAM LINK 2

Cloud based monitoring tool

Mimaki Cloud Technology PICT is a cloud-based printer status monitoring tool, allowing you to easily monitor your printer from your a PC or mobile device remotely.

PICT

Let’s get creative!

Request a demonstration

Brochures