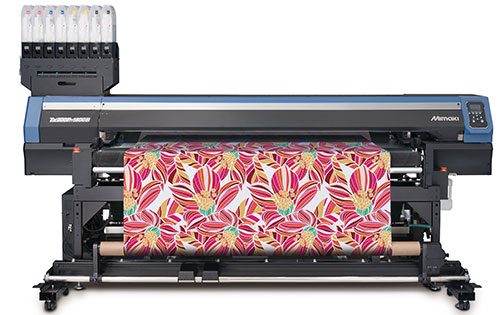

TX300P-1800B

High quality belt-fed direct- to-textile printer for stretchable fabrics

With its winning combination of quality, high speed and innovative automated belt-fed conveyance system, the Mimaki Tx300P-1800B has been developed to print direct to a broad range of natural and man-made fabrics. Particularly effective for printing on modern stretchable materials, the Tx300P-1800B is ideally suited to the production of fashion, clothing and soft furnishings.

|

|

|

|

|

|

|

|

Create…

Fashion and Apparel including Dresses, Shirts and Scarves;

Upholstery and Soft Furnishing Fabrics including Bed Linen, Cushions, Curtains and much more…

Specifications, options and supplies of TX300P-1800B

Specifications

| Item | Tx300P-1800B | |

| Printhead | On-demand piezo head (4 in-line printheads) | |

| Print resolution | 360dpi, 540dpi, 720dpi, 1,080dpi, 1,440dpi | |

| Drop size | Minimum 6pl, Maximum 24pl (Varies depend on ink type) | |

| Head height | Manual adjustment (2.0mm~7.0mm)*Standard:3mm | |

| Maximum print width | 1,880mm | |

| Maximum media width | 1,900mm | |

| Ink | Type/Colour | Sublimation dye ink: Sb420 (Bl, M, Y, K, Lbl, Lm) |

| Disperse dye ink: Dd400 (C, M, Y, K, R, Grey, Violet, Pink) | ||

| Textile pigment ink: TP400 (C, M, Y, K)*1 | ||

| Reactive dye ink: RC400 (C, M, Y, K, Bl, R, Or, Lk) | ||

| Acid dye ink: AC400 (C, M, Y, K, Bl, R, Or, Lk)*2 | ||

| Package size | 2L Ink pack | |

| Media thickness | 1.0mm or less | |

| Roll media weight | 40kg or less | |

| Roll diameter | φ250 mm or less | |

| Media type | Natural fibre (cotton, silk, hemp etc.) Chemical fibre (polyester, nylon etc.) | |

| Certification | VCCI class A, FCC class A, ETL UL 60950-1 CE Marking (EMC, Low voltage, Machinery directive, and RoHS), CB, REACH, RCM | |

| Power supply | Single-phase (AC100~120V/200~240V ±10%)×2 50/60Hz±1Hz | |

| Power consumption | AC100V : 1.44kW x2 / AC200V : 1.92kW x2 | |

| Interface | For print data: Ethernet 1000BASE-T / USB 2.0 Hi-speed For e-mail: Ethernet 10BASE-T / 100BASE-TX / 1000BASE-T | |

| Operational environment | Temperature: 20 – 30 °C (68 – 86 F°) Humidity: 35 – 65% Rh (Non condensing) | |

| Dimensions (WxDxH) | 3,197 x 1,798 x 1,845mm | |

| Weight | 627kg | |

Options and Supplies

| Item | Product No. | Remarks | |

| Sublimation dye ink: Sb420 | Blue | I-SB420-BLD-2L-1 | 2,000 ml Ink pack |

| Magenta | I-SB420-MD-2L-1 | ||

| Yellow | I-SB420-YD-2L-1 | ||

| Black | I-SB420-KD-2L-1 | ||

| Light blue | I-SB420-LBD-2L-1 | ||

| Light magenta | I-SB420-LMD-2L-1 | ||

| Disperse dye ink: Dd400 | Cyan | I-DD400-C-2L-1 | 2,000 ml Ink pack |

| Magenta | I-DD400-M-2L-1 | ||

| Yellow | I-DD400-Y-2L-1 | ||

| Black | I-DD400-K-2L-1 | ||

| Red | I-DD400-R-2L-1 | ||

| Grey | I-DD400-G-2L-1 | ||

| Violet | I-DD400-V-2L-1 | ||

| Pink | I-DD400-P-2L-1 | ||

| Textile pigment ink: TP400*1 | Cyan | I-TP400-C-2L-1 | 2,000 ml Ink pack |

| Magenta | I-TP400-M-2L-1 | ||

| Yellow | I-TP400-Y-2L-1 | ||

| Black | I-TP400-K-2L-1 | ||

| Reactive dye ink: RC400 | Cyan | I-RC400-C-2L-1 | 2,000 ml Ink pack |

| Magenta | I-RC400-M-2L-1 | ||

| Yellow | I-RC400-Y-2L-1 | ||

| Black | I-RC400-K-2L-1 | ||

| Blue | I-RC400-BL-2L-1 | ||

| Red | I-RC400-R-2L-1 | ||

| Orange | I-RC400-OR-2L-1 | ||

| Light black | I-RC400-LK-2L-1 | ||

| Acid dye ink: AC400*2 | Cyan | TBA | 2,000 ml Ink pack |

| Magenta | |||

| Yellow | |||

| Black | |||

| Blue | |||

| Red | |||

| Orange | |||

| Light black | |||

| Washing Liquid cartridge | SPC-0259 | Washing liquid for head cleaning.220ml cartridge | |

| Washing Liquid cartridge | SPC-0188S | Washing liquid for ink replacement.220ml cartridge | |

Our Sb420 ink is ECO PASSPORT by OEKO-TEX® certified.

Features of TX300P-1800B

Mimaki Advanced Pass System (MAPS)

MAPS is Mimaki’s unique anti-banding feature. To prevent banding, swath boundaries are overprinted and boundaries prone to banding are printed with fewer ink droplets.

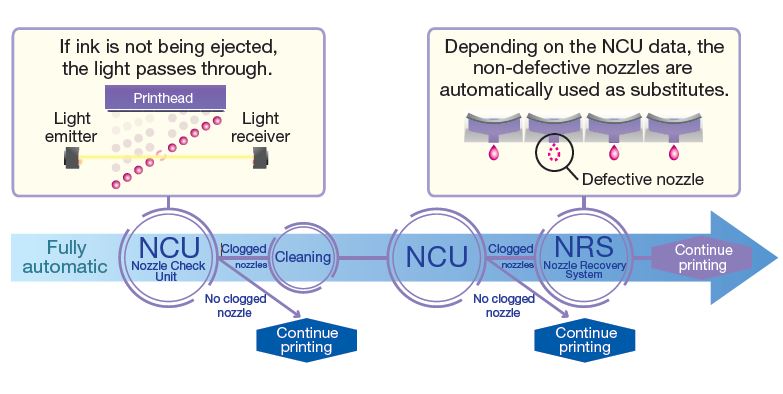

Continuous Uninterrupted Printing Features

Nozzle Recovery Function

In the event of a nozzle malfunction not being repairable by the use of the maintenance function, printing can continue by the use of another nozzle, without any loss of productivity or a reduction in image quality.

Uninterrupted Ink Supply System (UISS)

Two ink bottles per colour can be set with the UISS function. When an ink bottle runs out, another bottle of the same colour automatically starts supplying ink.

5 Ink types for a range of applications and textile types

| Ink type | Product name | Colour | Features | Application | Applicable fabric |

| Sublimation dye | Sb420 | Bl, M, Y, K, Lbl, Lm | Sublimation ink for direct printing. No transfer paper is required. | Soft signage | Polyester |

| Disperse dye | Dd400 | C, M, Y, K, R, Grey, Violet, Pink | Inks are fixed by heating and have high durability. | Industrial textile, Luxury apparel, Home furnishing | Polyester, nylon, acetate, and other fibres |

| Textile pigment | TP400 | C, M, Y, K | Simple post-printing process. No steaming, washing and drying processes are required. Inks are fixed only by heating. | Home furnishing | Cotton, hemp, and other fibres |

| Reactive dye | Rc400 | C, M, Y, K, Bl, R, Or, Lk | Inks produce a wide and vibrant gamut of colours, and have water resistance, light-fastness and rub-fastness, as dyestuff molecules bond with the fibres. | Apparel, Home furnishing | Cotton, hemp, silk, rayon, and other fibres |

| Acid dye | Ac400 | C, M, Y, K, Bl, R, Or, Lk | Inks produce vivid and brilliant colours on selected natural or synthetic fibres. | Apparel, Home furnishing | Wool, leather, silk, nylon, and other fabrics |

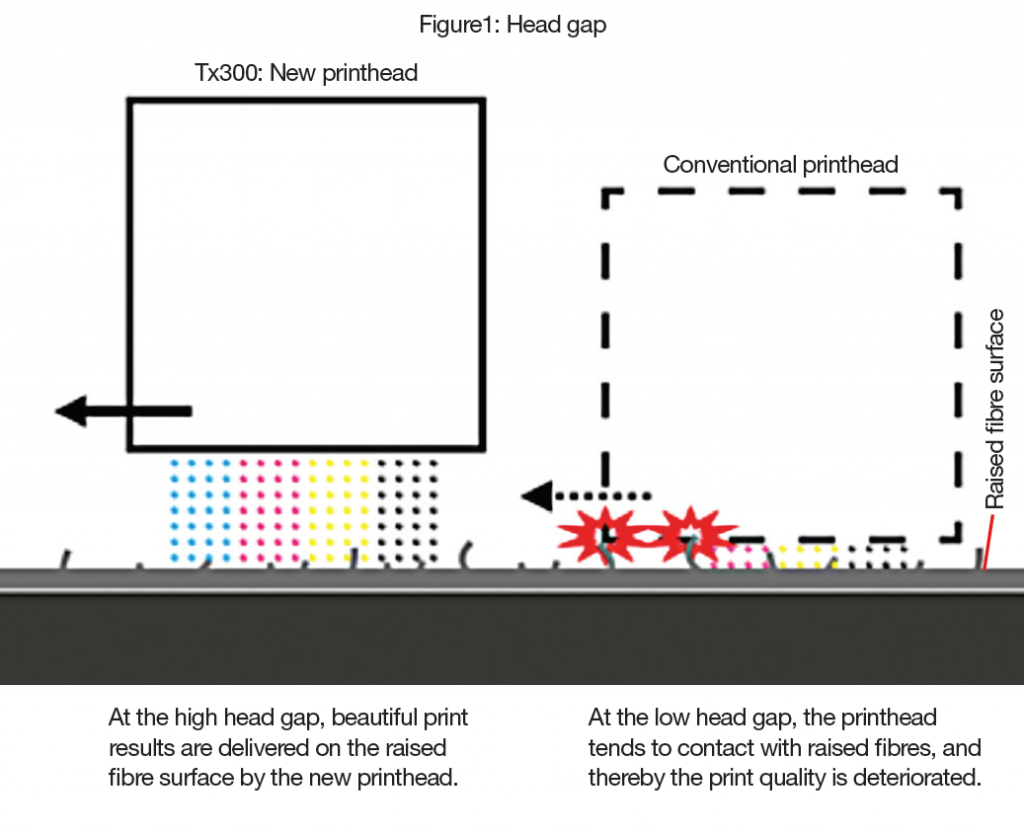

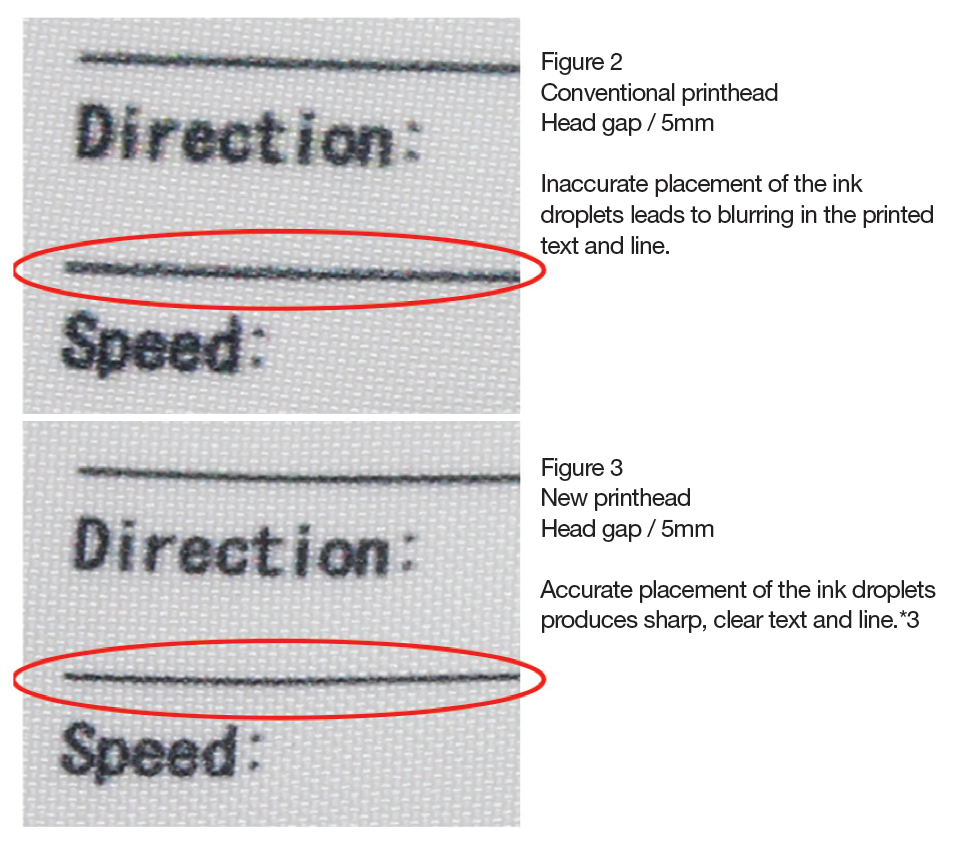

Adjustable higher head gap settings for thicker fabrics

- While printing on raised fibre surface textiles, a high head gap setting is required to prevent contact between the printhead and any raised fibres. (FIG.1)

- On more conventional models, restricted head gap reduces the accuracy of ink droplet placement. (FIG.2)

- The Tx300P-1800B employs a new advanced printhead with a high head gap to ensure accurate ink droplet placement, thereby enabling high-quality printing on a wide variety of fabric types. (FIG.3)

- The head gap is now fully adjustable from 2mm up to 7mm in 0.05mm increments, which enables printing on a wide range of different thicknesses of fabric.

Click on images to enlarge.

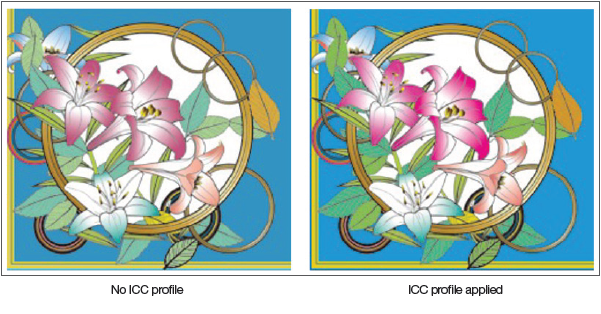

High performance TXLINK3 Lite RIP software

Desired colours can be represented by specifying the ink volume of each ink colour.

- Create desired colours

When the printed colour differs from that expected, the colour replacement function enables a user to specify the desired printing colour as the target colour. This function is useful for reproducing corporate colours. - Colour replacement by swatch book / named colour

Frequently used colours can be registered in a list, to allow automatic colour replacement when the file is opened in the RIP. - Easy to create different colour data

- Colour chart printing

Both ‘Swatch Book’ and ‘Named Colour’ have a ‘Print Similar Colours’ function, which enables similar colours to the colour selected to be printed as a chart.

2. STEP AND REPEAT

Large seamless patterns can be produced from a single image, including repeat and mirror patterns.

3. MULTICOLOUR ICC PROFILE CREATION

ICC profiles can be created simply to match a target colour by following the wizard.

Colour profile creation procedures:

- Specify the ink colour for each ink slot.

- Set the total ink limit: Print the ink limit chart, then set the maximum ink volume.

- Measure the ink density error: (Adjustment of ink density gradation) Each ink density is measured. Density is automatically calculated and adjusted.

- ICC profile creation: Measurement of the configuration chart printed from Colour GPS, The profile is automatically created.

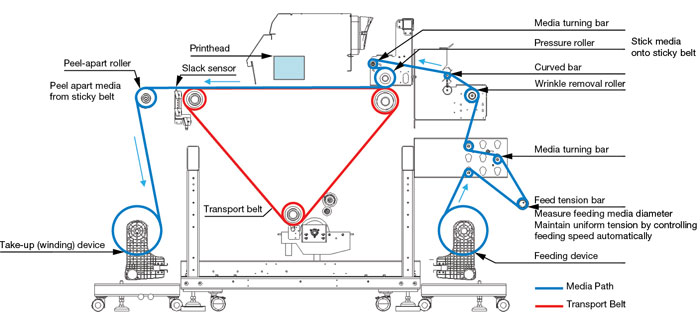

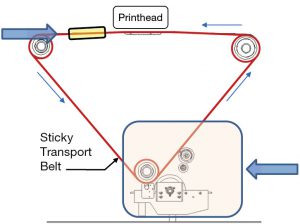

Belt transfer system for optimum print quality on stretchable fabrics

Stable feeding and transportation of the printable fabric is crucial for high quality direct-to-textile printing. Mimaki’s advanced belt-fed technology, incorporating a ‘sticky belt’ transport system ensures high levels of accuracy and image quality even when working with stretchable fabrics.

Sticky belt transport system incorporating belt washing facility

The ‘Sticky Belt’ transport system ensures consistent, high quality printing on stretchable or thin fabrics and is further enhanced by the following additional functions:

- Built-in Belt Washing Mechanism is designed to automatically remove struck-through ink residue from the belt. The mechanism also helps prevent any accumulation of dirt on the belt, thereby maintaining the adhesive qualities of the belt.

(NB: when not required, this function can be turned off to prolong the life of the adhesive belt) - Improved Correct Feed Control (CFC) incorporates a high resolution encoder unit to measure any belt movement more accurately enabling more effective control of feed length and drive rollers.

Sophisticated RIP software maximizes the performance of Tx300P-1800B

Our Sb420 ink is ECO PASSPORT by OEKO-TEX® certified.