REVOLUTIONIZE TEXTILE PRINTING: FAST, ECO, HYBRID

Waterless printing with hybrid power for stunning colours

Next-Gen hybrid textile printing for vibrant, eco-friendly textiles

The Tx330-1800 is a hybrid printer capable of handling both fabrics and sublimation, while the belt-driven Tx330-1800B model excels with stretchy or thick fabrics.

The Tx330 Series employs eco-friendly “waterless” technology, eliminating the need for pre-treatment, steaming, and washing, and drastically reducing water usage and environmental impact. The advanced Mimaki inks used in this series guarantee durable, vivid colours, while innovations such as nozzle recovery and easy maintenance boost productivity.

Unique features

- Eco-friendly “waterless” printing:

Reduces water use by eliminating pre-treatment, steaming and washing.Conventional textile printing requires large amounts of water for pre-treatment, steaming and washing. The Tx330 Series eliminates these steps, reducing water consumption and environmental impact while maintaining high-quality prints.

Reduces water use by eliminating pre-treatment, steaming and washing.Conventional textile printing requires large amounts of water for pre-treatment, steaming and washing. The Tx330 Series eliminates these steps, reducing water consumption and environmental impact while maintaining high-quality prints.

- Hybrid printing technology:

Prints on fabrics and sublimation paper, with belt transport for handling demanding textiles.The Tx330-1800 printer can switch between printing on textile and sublimation paper. Whether you need bright clothing or high-detail soft signs, its two ink types offer unmatched flexibility. The Tx330-1800B has a sticky belt that moves the textiles easily, even if they are stretchy or thick.

Prints on fabrics and sublimation paper, with belt transport for handling demanding textiles.The Tx330-1800 printer can switch between printing on textile and sublimation paper. Whether you need bright clothing or high-detail soft signs, its two ink types offer unmatched flexibility. The Tx330-1800B has a sticky belt that moves the textiles easily, even if they are stretchy or thick.

- Advanced Mimaki inks:

High-vividness, durable colours, with an extended green colour gamut.Mimaki’s high-performance inks deliver vivid, long-lasting colours. The TP410 pigment ink has an expanded colour range, including a new green special colour, for excellent colour reproduction and quality on different fabrics.

High-vividness, durable colours, with an extended green colour gamut.Mimaki’s high-performance inks deliver vivid, long-lasting colours. The TP410 pigment ink has an expanded colour range, including a new green special colour, for excellent colour reproduction and quality on different fabrics.

- Automatic maintenance features:

Nozzle recovery and automatic belt washing ensure minimal downtime.The Tx330 Series is designed to be easy to use. It includes nozzle recovery and automatic belt washing systems. These features improve printing quality and stability, reduce the need for manual maintenance, and maximise uptime for continuous production.

Nozzle recovery and automatic belt washing ensure minimal downtime.The Tx330 Series is designed to be easy to use. It includes nozzle recovery and automatic belt washing systems. These features improve printing quality and stability, reduce the need for manual maintenance, and maximise uptime for continuous production.

Designed to produce a wide range of textile applications for different markets.

Soft Signage, Event and Decoration, Fashion, Sportswear, Home Decoration.

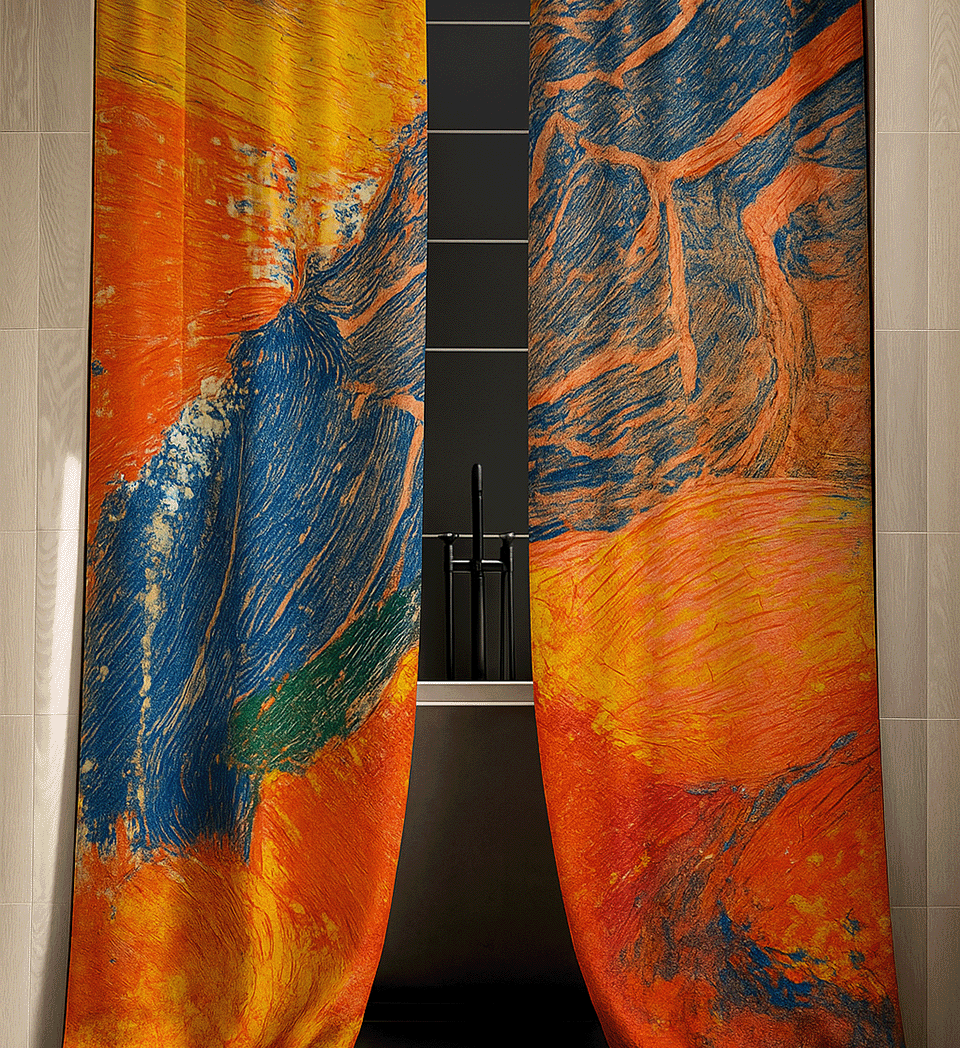

HOME & INTERIOR DECOR

CUSTOM TEXTILE

FASHION & APPAREL

SOFT SIGNAGE & PROMOTIONAL

TRADESHOW GRAPHICS

SPORTSWEAR & ACTIONWEAR

Versatile ink options with advanced hybrid technology

The Tx330 Series uses three specialised inks for different applications.

TP410 textile pigment ink is ideal for printing directly onto natural fabrics such as cotton and hemp. Its 8-colour set includes special green and red for more vibrant prints.

Sb420 dye sublimation ink works well with polyester and is perfect for flags and banners. It offers high back-through performance for double-sided printing.

Sb411 dye sublimation ink is great for dye transfer applications that require high colour fastness and durability.

All inks also meet strict environmental standards and support hybrid transitions between ink types.

For even more confidence

our inks are are bluesign® approved and OEKO-TEX® certified

Sb411 and TP410 inks are bluesign® approved and ZDHC MRSL Lv.3 certified, meeting the highest sustainability standards with minimal environmental impact and ensuring worker safety.

Sb411 and Sb420 are also ECO PASSPORT by OEKO-TEX® certified, confirming their suitability for skin-friendly textiles.

This printer is packed with Mimaki Core Technologies that offer the best print quality, maximum productivity and reduced exposure to risks that can delay production. See below list of core technologies that are included in the Tx330 Series.

For continued productivity

- Nozzle Recovery System (NRS), to replace missing nozzles

- Automatic Cleaning Function, to keep the print head clean

- Uninterrupted Ink Supply System (UISS), for uninterrupted ink supply

For quality printing

- Mimaki Advanced Pass System (MAPS4), to reduce banding

- Waveform Control (WFC), for best possible image sharpness

- Variable Dots Technology (VDT), for smoother gradations

- Mimaki Weaving Dot Technology (MWDT), to reduce streaks and unevenness

- Dot Adjustment System (DAS), for stable printing

| Model | Tx330-1800 | Tx330-1800B | |

| Print head | On-demand piezo head (2 staggered layout) | ||

| Print Resolution | X: 300, 600; Y: 600, 900, 1.200, 1800 dpi | ||

| Ink Type | Sb420, TP410, Sb411 | Sb420, TP410, Sb411 | |

| Ink | Sb420 | 4-colour: M, Bl, Y, K 6-color: C, M, Bl, Y, K, Lb, Lm | 4-colour: M, Bl, Y, K 6-color: C, M, Bl, Y, K, Lb, Lm |

| TP410 | 4-colour: M, C, Y, K 8-colour: M, C, Y, K, R, G, Bl, Lk | 4-colour: M, C, Y, K 8-color: M, C, Y, K, R, G, Bl, Lk | |

| Hybrid | Sb411: M, Bl, Y, K / TP410: M, C, Y, K Sb420: M, Bl, Y, K / TP410: M, C, Y, K Sb411: M, Bl, Y, K / Sb420: M, Bl, Y, K | Sb420: M, Bl, Y, K / TP410: M, C, Y, K | |

| Capacity | 2L Ink Pack | ||

| Max. Print Width | Fabric: 1.910mm Paper: 1.940mm | Fabric: 1.890mm | |

| Print margins | 15mm (default), minimum: 5mm | ||

| Media | Max. Width | Fabric: 1.920mm Paper: 1.950mm | Fabric: 1.900mm |

| Thickness | Max. 5,0mm | ||

| Transport | Roll-to-Roll with pinch-rollers | Roll-to-Roll with belt transport | |

| Roll external diameter | Max. 250mm | ||

| Paper core internal diameter | 2-inches or 3-inches | 1~1.5-inches, 2~3-inches | |

| Roll weight | 40kg or less | 40kg or less (2~3″ core) 34kg or less (1~1,5″ core) | |

| Interface | Ethernet 1000BASE-T (Recommended), USB2.0 Hi-Speed | ||

| Languages | English, Japanese, Chinese, Turkish, Portuguese, Spanish, Italian, Korean | ||

| Power supply | AC100~120V/200~240V±10% 3A 50/60Hz±1Hz | AC100~120V/200~240V±10% 5A 50/60Hz±1Hz | |

| Power consumption | Max. 300W or less / Minimum 4,5W or less | Max. 500W or less / Minimum 4,5W or less | |

| Certifications | VCCI class A, FCC class A, ETL IEC 62368-1, CE Marking (EMC, Low voltage, Machinery directive, and RoHS), CB, REACH, Energy Star, RCM, KC, UKCA | ||

| Dimensions (WxDxH) | 3.230mm x 965mm x 1.857mm | 3.230mm x 1.912mm x 1.900mm | |

| Weight | 291kg | 622kg | |

Software RIP

The primary task of RIP (Raster Image Processor) software is to convert the different formats of the file to be printed into data that the printer “understands” as raster data.

TxLink5 Lite

Software RIP

The primary task of RIP (Raster Image Processor) software is to convert the different formats of the file to be printed into data that the printer “understands” as raster data.

RasterLink7 (Optional)

Sb420

Direct sublimation ink

Mimaki’s SB420 ink is a high-performance dye sublimation ink for both direct printing and sublimation paper that delivers vivid colours and high back-through performance for vibrant two-sided prints on flags and banners. It ensures environmentally friendly and stable long-run production on various polyester fabrics.

Packaging

Colour

Ink type

TP410

Textile pigment ink

TP410 is an 8-colour textile pigment ink with special red and green colours for high quality prints. It is fade and light resistant, requires no pre-treatment and is environmentally friendly. Ideal for fashion, home décor and customised textiles.

Packaging

Colour

Ink type

Sb411

Paper transfer sublimation ink

Sb411 produces bright and vivid colours with good light-fastness and extreme good rub- and wash-fastness. Fixation by heat with calendar or flat heat press.

Packaging

Colour

Ink type

More info Tx330 Series

Request a demonstration